Leaderboard

Popular Content

Showing content with the highest reputation on 12/07/21 in all areas

-

While casually perusing the likes of Aliexpress I discovered someone was selling one piece HSH mahogany strat bodies for something like US$65. So maybe it's time to dip my toe in the water and see how bad things really get. The same seller had flamed maple necks available. "Oh," I thought. "There's a good chance of them fitting if they're made by the same company". [Cue: foreshadowing] So the parts arrived and first impressions were very good. The grain on the flamed maple necks was stunning, one more so than the other. The bodies were incredibly light, the average weight for a mahogany strat body is 2kg, the ones I received clocked in at 1.7kg (with slight figuring) and 1.5kg for a plainer body. However there were issues, as expected. The first was they sent 21 fret necks with truss rod adjustment at the heel. And the bodies didn't have a recess for the truss rod tool. Normally, they wouldn't exchange a neck (despite guarantees on the listing they would) but because I'm in the same country postage was quite cheap, it was feasible. I asked them to exchange one neck for a 22 fret version with the headstock adjustment and more intense flaming. They'll send me a few photos of replacement necks to choose from later today.1 point

-

Speaking of HSS, I spent quite a bit of time thinking about what to do with these bits and pieces. The mahogany will probably make the instruments too warm for tradition strat sounds (although given how light the mahogany is, that isn't totally certain). But using humbuckers seemed to be a safe bet: Partscaster #1: A bit of a Scream Queen. This will be a light guitar with HSS layout and extra routing out the back of the instrument for the sustainer circuitry like the Ed OBrien strat. I have a sustainer installed in another guitar from NZ which I'm going to remove and reinstall in the lighter partscaster to turn it into a bit of a screamer. Some say basswood is a great wood to use with a sustainer but the first guitar I had it installed in was mahogany and it sounded great and 1.5kg, it might get within spitting distance of alder. Back in the eighties, the resident bass expert in my preferred music store in NZ was a Londoner by the name of Steve Hyde. He was heavily into goth/new romantic but died of a sudden heart attack about twenty years ago but he and I shared an interest in the UK music scene at the time. His first bass was a Shergold Marathon which he'd repainted by bombing it with spray cans of flourescent green, purple, pink and blue paint. I really loved that paint scheme and always wanted to do one of my own but mine will be slightly different (no green) and have a clear 2k lacquer over the top. Partscaster #2: Something heavier. The second body weighs 200g more and features slight figuring over the body. There is a strong temptation to leave it as natural, at least in the beginning until I see how much the body pops. I had a guitar tutor at high school who had a late 70's/early 80's Schecter Partscaster with all brass hardware and a mahogany body. So I was thinking about going down the gold route as it might look nice against the warmth of the body and neck. Don't know though - the biggest hurdle will be finding a Chinese made gold anodised HSH pickguard. But for the electronics I've pretty much decided to go with Dimarzio FRED in the bridge and Air Zone in the neck for jazzier sounds with something from my parts department for the middle single coil (a cheap Powered by Lace stacked humbucker which will need a black pickup cover I expect). I'll probably get a prewired harness and modify it for a push pull vol for coil splitting both the humbuckers and maybe figure out a cost effective method for getting neck and bridge in the middle position. After I've fixed the neck and body as far as possible and finish sanded to about 400 grit, I'm going to experiment sealing the grain with CA. The one great thing about all of this is that locally sourced parts are between 50% to 90% the cost of what I might pay in the UK. So there's room to play around and change things later if I don't like them. Right now, I've sourced an eighteen quid router, the router bits and clamps for mere pence and now need to get some MDF plus epoxy putty from which to make neck heel and pocket templates. Then I'll be in a position to plan the remedial routing.1 point

-

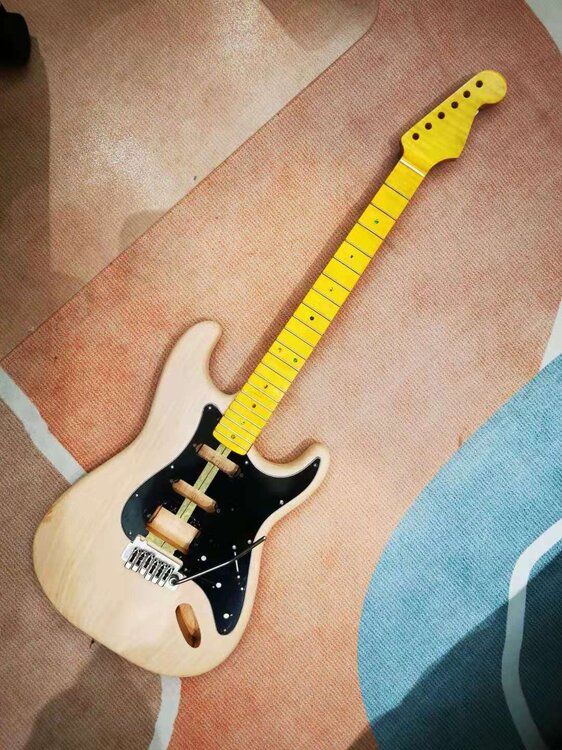

In the meantime, I decided to check bodies and necks for accuracy by drawing centre lines and checking alignment: 1) Neck pocket wall and end of neck heel didn't fit and the pocket was 1mm too wide. Reviews warned me of this so it wasn't a total surprise. I bought a black three ply HSH pickguard and checked the pocket on that against the body. It aligns surprisingly well although still too wide (58mm, rather than 56) but the fit issue must be the neck heel. Sure enough, the curve is asymmetrical. 2) The floor of the neck pocket is uneven. There's no excuse for this really, it's just sloppy paths in the milling software. 3) I did a quick check of neck alignment as best I could using cotton thread. The alignment might be out by 2-3mm but it needs checking with straight edges to be sure. 4) The trem cavity was unfinished along one long side and a trial fit of the bridge suggested it might need widening for full function. I bought a router bit specifically designed for under cutting the top rout by about 3mm. So with the bridge, neck, HSS pickguard for one of the bodies I did a trial fit just to give me a sense of what to expect.1 point